What are you looking for today?

Enter your keyword and press "Enter"

514-331-0062

Anodized aluminum sheets are available in clear, champagne, light bronze, medium bronze, dark bronze, gold and black. These color options offer design flexibility to suit different styles and preferences. Whether you’re looking for a sleek, modern aesthetic with black, a bright luminosity with clear, or a warm tone with the other colors, you can find the color that best suits your project. These colors add an attractive visual dimension to anodized aluminum plates, making them versatile for a range of applications such as architecture, interior and exterior decoration, and much more.

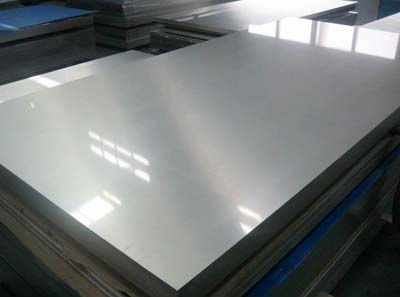

Anodized aluminum plates are made from alloy 5005 and are offered in various sizes and thicknesses. They offer a variety of length options, including 4′ x 8′, 4′ x 10′, and many others. Anodized aluminum sheets guarantee enhanced strength and durability thanks to the anodizing process, which forms a protective alumina layer on their surface. Whether for architectural, industrial or decorative applications, these anodized aluminum sheets meet a variety of needs and offer an elegant, long-lasting aesthetic.

The anodizing process is a chemical surface treatment method that involves successively immersing an aluminum part in different baths (acid and electrolytic), followed by rinsing with demineralized water. Several aluminum anodizing techniques are available, depending on the product’s intended use. When the aluminum part comes into contact with this solution, an oxidation reaction takes place on its surface. The aluminum oxide that forms creates a thin layer of alumina, which acts as a protective barrier for the material. This protective layer then enables the part to be tinted, offering a variety of finishes, such as matte, satin or gloss.

Anodizing gives aluminum parts greater resistance to corrosion, while improving their aesthetic appearance. It also enhances scratch resistance and makes the part harder. Another advantage of anodizing is the ability to give the part a specific colour. By tinting your profiles in this way, you can give your creations a highly aesthetic finish.